FAMILY OWNED

A timeline of Rivertrace Engineering’s history throughout the years for you to explore.

-

1983

Rivertrace Engineering is founded!

In the early years the initial Rivertrace product range comprised two 15ppm oily water separator monitors, our OCD1 and OCD2 models.

-

1989

Expansion into Offshore

In 1989 the company expanded into the offshore industry, producing a range of custom-made oil-in-water analysers for a variety of applications. As a result we quickly became a leading supplier to North Sea oilfield operators

-

-

1990

Commission of a OCD28

Mike from Rivertrace finding himself offshore on an oil rig during the commissioning of an OCD28. The OCD 28 series was an OCD2 (range 0-30 ppm) with an autoclean system. Rivertrace also had an OCD 38 which was an OCD3 (range 0-200 ppm) with an autoclean system.

-

1994

OCD1 and OCD2 models superseded

In 1994, the OCD1 and OCD2 were superseded by the OCD1M and OCD2M models.

-

1995

OCD10M launched

In the early 1990s we received numerous requests for oil discharge monitoring systems from clients who thought that existing designs had room for improvement. In conjunction with our customers we drew up the specification for a new ODM that could not only meet IMO regulations, but still improve on the performance of equipment available at that time. The Rivertrace Oil Discharge Monitor OCD10M was launched in late 1995.

-

1997

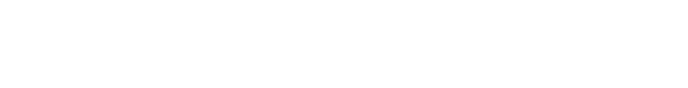

Celebrating the OCD50M

OCD50M the highly sensitive and successful OCD50 series for boiler condensate monitoring is released.

-

2000

The RTE Workshop expands

As Rivertrace grows our workshop needs an even larger calibration rig!

-

2000

OCD CM introduced

The OCD1M and OCD2M were replaced by the OCD CM in response to the introduction of IMO resolution MEPC 60(33) in 2000.

-

2001

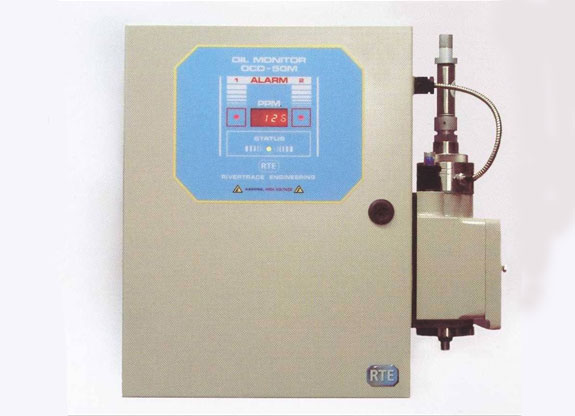

OCD CW designed

In 2001 the OCD CW was designed as a low cost solution for simple cooling water monitoring applications.

-

2002

RTE moves to new premises in Redhill

Rivertrace expansion means it needed to move! We relocate to a new premises in Redhill which offers both larger office, administration and workshop space. These premises provide the base for Rivertrace to this very day.

-

2003

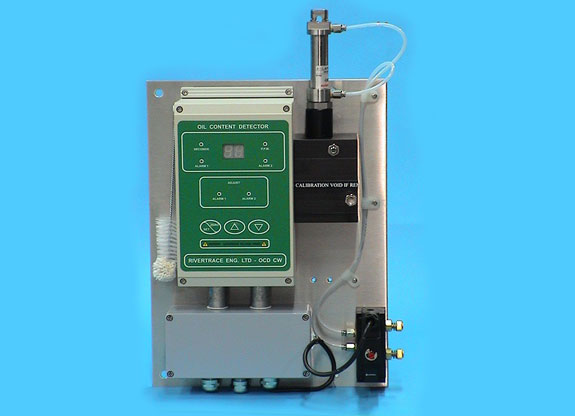

OCD Xtra technology

The OCD Xtra technology to combine multiple light wavelengths with multiple sensor technology was developed to accurately measure the oil content in the blackest of produced water.

-

2004

SMART BILGE replaces OCD CM

The IMO resolution MEPC 107 (49) for the revised guidelines and specification of pollution prevention equipment for machinery space bilges of ships was adopted in July 2003, led to the development of the SMART BILGE to replace the OCD CM . The “Smart-Bilge” monitor was launched in 2004 to comply with the new IMO resolution MEPC 107 (49) applicable from the 1st January 2005.

-

2005

A new Smart ODME design

As a result of the changes in IMO regulations and the introduction of MEPC 108 (49) – also applicable from 1st January 2005 – a new ‘Smart ODME’ design was introduced featuring advanced measuring principles.

-

2006

The Smartsafe Bilge Overboard Security System

The Smartsafe Bilge Overboard Security System was developed in response to our customers’ worldwide requests and requirements for additional security from the industry issues of Magic Pipes.

-

2007

Finalists!

Rivertrace was a finalist in the 2007 Lloyds List Clean Sea Awards. This is our management team looking very happy ...

-

2008

Mike at 25!

Mike Coomber reaches the grand total of 25 years as the Managing Director and Owner of Rivertrace. Throughout these years he has been the engineering brain behind all of our development and the smiling face at exhibitions.

-

2010

Showcasing the SMART ODME

Our Sales Director Graham North is showcasing our complete SMART ODME system at SeaWorks Asia

-

2012

SMART 50M launches

Rivertrace launches the SMART 50M to replace the OCD 50M as a boiler condensate monitor.

-

2013

Training session in China

Training session with new Agent Winkong Marine Engineering in China.

-

2013

Knowledge Transfer Programme with Brighton University

In 2013 we completed a Knowledge Transfer Programme with Brighton University to develop the technology of Microscopy to measure oil content in a sample stream. From this we launched our SMART PFM 107 accredited to MEPC 107 (49).

-

2014

Smartsafe ORB

The SMARTSAFE ORB is the next generation of the Smartsafe. This system records the oily water discharge process of any Oil Water Separator (IMO - MEPC 60.33 or 107.49) thus avoiding the common mistakes of manual entries and log variations in the oil record book.

-

2015

Agents Seminar in Greece

Rivertrace hosts its first Agents Seminar in Athens Greece with our principal agent Technava.

-

2016

Bio Fuels

The amendment of MEPC.240(65) to the MEPC 108(49) comes into force on the 1st January 2016 which means vessels carrying bulk blends of petroleum oil and bio fuels require a compatible ODME system. In response to this Rivertrace updated our SMART ODME to include Bio Fuels as per MEPC 240 (65).

-

2016

RTE becomes Rivertrace Limited

Rivertrace is restructured and rebranded from Rivertrace Engineering Limited (RTE) to Rivertrace Limited.

-

2018

Golf Day!

The Rivertrace Golf Day in May 2018. The sun was shining and all handicaps tested!

-

2018

Addition of the Smart WiO

Rivertrace expanded their product range with the addition of a new Smart WiO - Water in Oil sensor that continuously monitors dissolved water content in oil allowing ship operators to proactively limit the risk of engine and machinery corrosion.

-

2019

Scrubber Washwater monitoring

With the pending sulphur cap regulations in sight, Rivertrace used their marine experience to develop a unique Smart ESM as per MEPC 259(68) to monitor the Scrubber Washwater for PAH, Turbidity, and pH.